We prioritise

a growth strategy

We are healthcare growth strategy experts, unlike big consulting organisations that alternate between operational and diverse strategy work.

Colloborative efforts between researches, engineers, and production teams to optimize production efficiency and effectiveness.

We are dedicated to using quality as a competitive advantage in addition to complying with quality criteria.

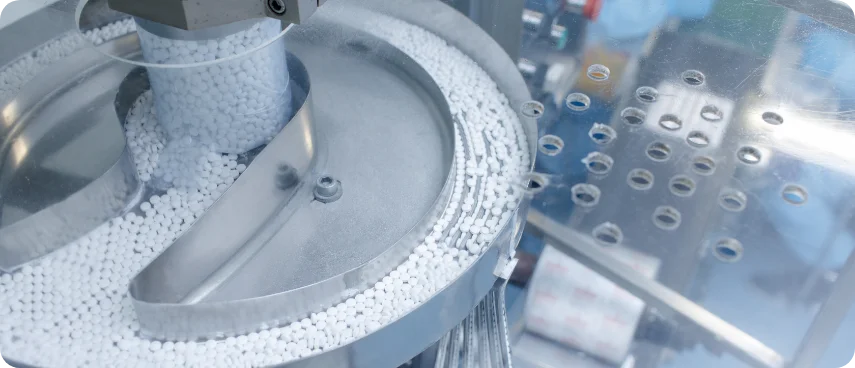

The company has a State-of-art manufacturing facility spread over a 32,000 sq. ft. area, at Prernapith, 15km from Ahmedabad. The facility is FDCA Gujarat & WHO-GMP approved. The facility consists of production and quality control with modern equipments along with a strong formulation and development department to build in quality by design.

Manufacturing operations are monitored by the Quality Assurance department with effective quality management systems. A competent technical team ensures the best quality of the product and adds an edge to the growth of the company.

The building also has a level for finished products storage and a store for raw and packaging materials, as well as a quality control laboratory with separate sections for a chemical lab, and instrument lab, and a microbiological lab.

Aneta maintains strict quality control because it adheres to high quality standards. The business has taken every precaution to include significant quality control tools such practices are implemented as per GLP norms.

Aneta has the tools necessary to produce tablets and capsules. For tablets and capsules. Its estimated capacities under three shifts are as follows:

Dakin Chiller: Aneta has Dakin chillers (02 Nos.)

having a capacity of 300 TR.

Boiler: Aneta has Forbes Marshall with a capacity of

1120 Kg/Hour

We are healthcare growth strategy experts, unlike big consulting organisations that alternate between operational and diverse strategy work.

We take great satisfaction in highly innovative answers to challenging issues. We both have a love for using persuasive narrative, solid business arguments, and practical advice to assist our customers develop winning plans and earn the support of their organisations.

We support making decisions based on facts. Our consulting strategy is characterized by insight development and quantitative precision. We are professionals at creating research to support quantitative models, creating projections in cutting-edge and emerging markets, and quantifying the indescribably tough.

Above all things, we place a great importance on cooperation and partnership, and we plan our engagements to be very iterative. We get things going quickly to changing customer demands. Our top executives maintain a high bar for quality throughout our engagements and are actively involved.

Aneta has in place a thorough quality control system and labs that cover every step of the production process, from raw materials to finished products. This involves testing and analyzing raw ingredients regularly and in-process and final product testing to verify that our products meet or exceed regulatory criteria for safety and efficacy.

Raw ingredients and finished products are tested using proven methods and equipment following defined procedures. Physical, Chemical, and Microbiological Tests are performed to confirm that the items fulfill the essential specifications for Identification, Purity, Potency, and Safety.

With the use of dedicated Equipment, Cleaning Methods, and Employee Training, our manufacturing facilities are intended to reduce the danger of cross-contamination. We also check the environment regularly to verify that our facilities satisfy set cleanliness requirements.

We have a comprehensive change control procedure in place that necessitates a full assessment of any proposed modifications to our production processes or equipment. This comprises assessing the possible impact on product quality, followed by validation and testing to verify that the modifications do not have a negative impact on product quality or safety.

For its raw ingredients, excipients, and immediate, Aneta has a stringent vendor qualification and monitoring procedure in place. This includes inspecting raw materials in its well-equipped QC lab as well as analyzing documentation and records of quality control methods supplied by the supplier. Aneta also has a system in place to continuously monitor and assess our suppliers to ensure that they continue to meet our quality requirements. Any non-compliance with raw material quality by suppliers is unacceptable to Aneta.

We have a strong quality management system in place to guarantee that all applicable regulatory standards are met. This involves keeping the necessary licenses and certifications, creating and adhering to standard operating procedures, performing frequent internal audits and assessments, and remaining current on regulatory changes. We also collaborate closely with regulatory agencies to ensure that our quality control methods and products comply with all applicable standards and recommendations.

We collaborate extensively with each client to comprehend their specific quality requirements and to create a quality control strategy that satisfies their objectives. This includes defining important quality traits, creating acceptance criteria, and implementing product-specific testing techniques and processes. We also give our clients frequent updates and progress reports to ensure that they are happy with our quality control systems.